Why UNIVER Machine? Where is the difference between prices?

Welcome to Download the Technical Comparision Document For Unitest-H Series Universal Testing Machines

UNITEST-H Series (Dual Space) Servo-Hydraulic Universal Testing Machines are designed for high-capacity tension, compression, bending/flexure, and shear testing. Engineered to fully comply with international standards including BS, EN, ISO, ASTM, JIS, and GB, these systems deliver reliable and accurate performance across diverse applications. The dual-space design allows users to quickly switch between tension and compression tests without the need to remove heavy fixtures.

Integrated upper and lower test spaces on one frame — the upper space for tension tests and the lower space for compression, bending/flexure, and shear tests. No tooling change is required to switch between tensile and compressive testing.

Dual-spindle adjustment allows quick vertical repositioning to accommodate specimens of varying lengths and heights. Multiple models are available to meet different testing demands.

Suitable for standard bars and plates, as well as PC strands requiring extended clamping lengths for optimal grip force.

Unlike conventional closed-frame grips, Univer’s semi-open configuration offers superior stiffness, easier specimen setup, and higher long-term reliability.

Enables smooth specimen installation and removal, significantly reducing effort compared to manual systems. A portable grip control box enhances convenience.

Provides excellent axial and lateral stiffness with minimal maintenance and low reaction at specimen failure.

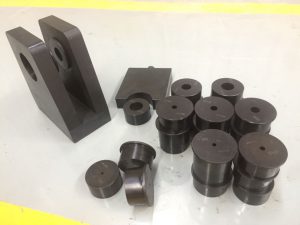

Supports diverse test configurations, including tension, compression, bending/flexure, shear, and other specialized tests.

Chrome-plated columns and extensive stainless steel components ensure corrosion resistance, easy cleaning, and long service life.

Maintains operator visibility while ensuring safety during testing.

The 1000 kN model is nearly 1000 kg heavier than comparable machines in China, while the 2000 kN model is up to 2000 kg heavier, ensuring superior stability and performance.

Tensile Testing of Metallic Materials, such as steel bar, PC wire strands, steel plates, fasteners

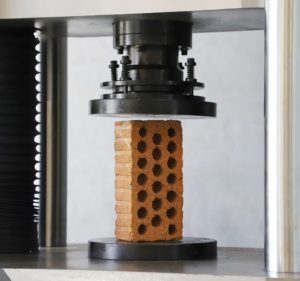

Compression Test of Concrete Cube and Cylinder

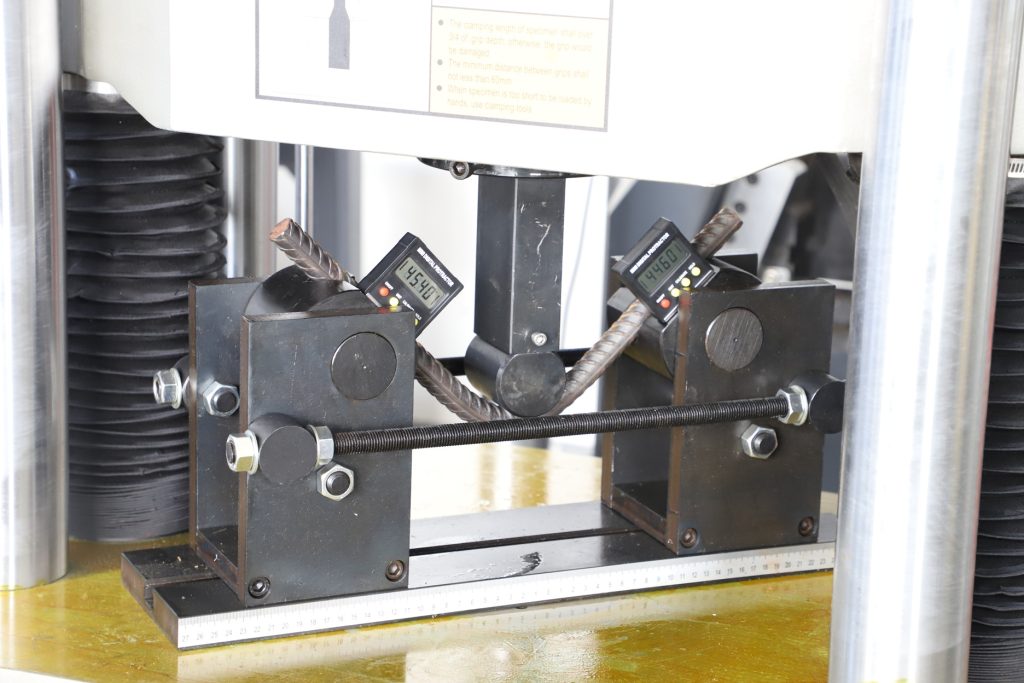

Bend Test for rebar

Flexural Test on concrete prism

Double Shear Test of bolts

Univer new innovation on grips for tensile testing of prestressed concrete strand/7 wire strand, directly clamp strand and breaks out of grips, ISO 15630-1, ISO 15630-3, ASTM A416.

Challenges to make suitable jaw insert for tensile testing of wire strand exist for decades in material testing industry, because wire strand is completely different with other steels typically rebar, the wire strand has very high hardness on surface, this makes jaw inserts are easy to worn out if the jaw inserts are directly contacting wire strand for tensile test, besides, the wire strand is brittle, any damages caused by jaw inserts will lead the breakage of sample inside grips and the test is surely judged as invalid according to test standards, because of these characteristics on wire strand, there are several gripping methods exist in the market, but none of them are easy to use, mostly take a lot of time to put the sample inside grips and also complication of removing add-on, some of them are costly such as aluminum plates wrapping method, the test cycles are very low in efficiency, especially for quality control labs who have a lot of samples need to be finished.

With the aim to improve the operation efficiency for tensile test of wire strand, Univer engineers have developed new type of jaw inserts for wire strand, these jaw inserts make the grips are easy to use as well as extreme long service life, the test just like the typical test procedure as what we did for rebar, directly mount the wire strand inside grips and start the test immediately.

Welcome to Download the Technical Comparision Document For Unitest-H Series Universal Testing Machines

Univer Launched New Servo-Hydraulic Universal Testing Machine

Univer Launched New Servo-Hydraulic Universal Testing Machine

Etiam magna arcu, ullamcorper ut pulvinar et, ornare sit amet ligula. Aliquam vitae bibendum lorem. Cras id dui lectus. Pellentesque nec felis tristique urna lacinia sollicitudin ac ac ex. Maecenas mattis faucibus condimentum. Curabitur imperdiet felis at est posuere bibendum. Sed quis nulla tellus.

63739 street lorem ipsum City, Country

+12 (0) 345 678 9

info@company.com